LPG

May 8, 2023

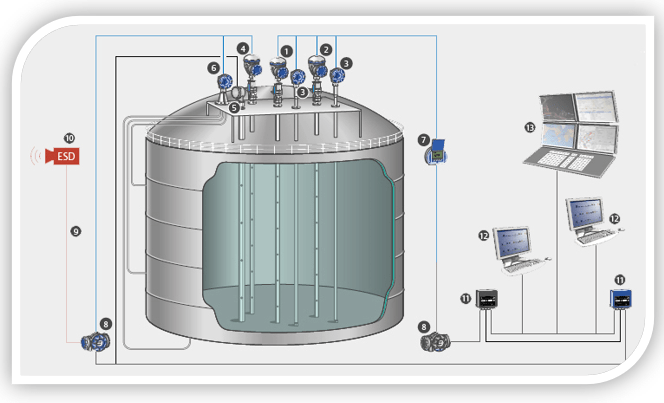

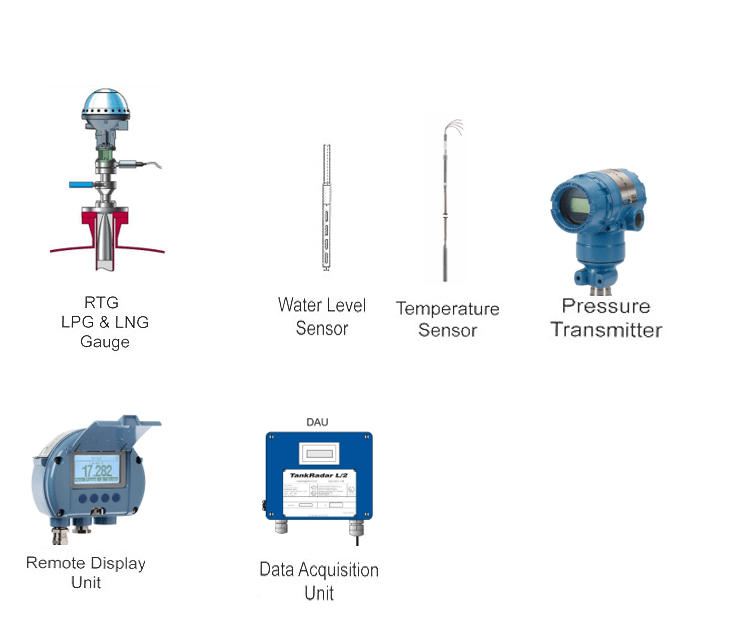

Tank Gauging System

اختصارات:

CCR: Central Control Room

CSS: Combined Safety System

ESD: Emergency Shutdown

EWS: Engineering Work Station

FAT: Factory Acceptance Test

FIU: Field Interface Unit

I/O: Input/Output

LAN: Local Area Network

LER: Local Equipment Room

LPG: Liquefied Petroleum Gas

LTD: Level, Temperature & Density Probe

MMI: Man Machine Interface

MTBF: Mean Time Between Failure

MTTR: Mean Time to Repair

OWS: Operator Work Station

OIML: International Organization of Legal Metrology

PCS: Process Control System

PSD: Process Shutdown System

PSU: Power Supply Unit

RTD: Resistance Temperature Detector

SAT: Site Acceptance Test

SIL: Safety Integrity Level

TGS: Tank Gauging System

UPS: un interruptible Power Supply

VDU: Visual Display Unit

مهمترین استانداردهای مورد استفاده در طراحی سیستم TGS (ساخت، تست و راه اندازی)

- API 551 Process Measurement Instrumentation

- API 552 Transmission Systems

- API 554 Process Instruments and Control

- API6D Specification for pipeline valves (steel gate, plug, ball and check valves).

- ASME PTC 19.3 Performance Test Code Temperature Measurement.

- BS 3463 Specification for observation and gauge glasses for pressure vessels

- BS 7671 Requirements of electrical installations. IEE wiring regulations.

- BS EN 50262. Metric cable glands.

- BS EN 837 Pressure Gauges: Selection and Installation Recommendations

- ANSI B 16.5 Pipe flanges and flanged fittings.

- IEC 60079 (all parts) Electrical Apparatus for Explosive Gas Atmospheres

- IEC 60529 Degrees of Protection Provided by Enclosures (IP Code)

- IEC 60751 Industrial Platinum Resistance Thermometer Sensors

- IEC 61000 Electromagnetic compatibility

- IEC 61520 Metal thermowells for thermometer sensors – Functional Dimensions

- ISA S.5.1. Instrumentation symbols and identification.

- ISA S.5.4 Instrument Loop Diagrams

- ISA 1 Annunciators – sequences and specification.

- ISO 9001:J994 or ISO 900 I:2000 (including design) Quality Management System requirements

- ISO 9002: 1994 Quality systems – model for quality assurance in production, installation and servicing

- NACE MR-01-75 Sulphide stress cracking resistant metallic material for oil field equipment.

- OIML R85 Dynamic Automatic level gauges for measuring the level of liquid in fixed storage tanks

مدارک رفرنس جهت خرید و نصب سیستم TGS:

- Instrumentation Control & Safety System Philosophy

- General Instrumentation Technical Specification

- Specification for Instrument Piping material

- Specification for Instrument Cable

- PID – propane, butane, condensate, pentane &… storage tanks

- Mechanical data sheet

- Site, Environmental and Utility Data

- Painting Specification

مشخصات فنی مورد نیاز جهت خرید و نصب سیستم TGS:

- a) Supply and Functional Specifications

- b) TGS general architecture and cable block diagram

- c) Data sheets and calculation notes (if applicable)

- d) General Arrangement (Instrument, JB, Panels, etc.)

- e) Instrument Hook-up drawings

- f) Cable list and interconnection drawings

- g) Instrument loop diagrams

- h) Layout and Wiring Diagrams (Instrument, JB, Panels, etc.)

- i) I/O list & assignment, Graphic displays drawings

- j) List of data to be exchanged with the PCS (bus/memory mapping or hardwired),

- k) Calibration Procedures

- I) Hazardous Area Certificates

- m) FAT & SAT procedures

- n) Test Results

- 0) Recommended spare parts for start-up and commissioning

- p) Recommended spare parts for 2 years operation

گواهینامه ها و مدارک بازرسی لازم جهت خرید تجهیزات:

- The conformity certificates.

- The test and calibration certificates for all instruments.

- The electrical hazardous area certificates (EEx, IS) for all instruments.

- The material certificates.

- The air pressure tests certificates.

- The hydraulic pressure tests certificates (if applicable).